ICS & KWA Advanced Hop-up Chamber & Inner Barrel O-Ring

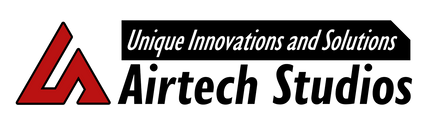

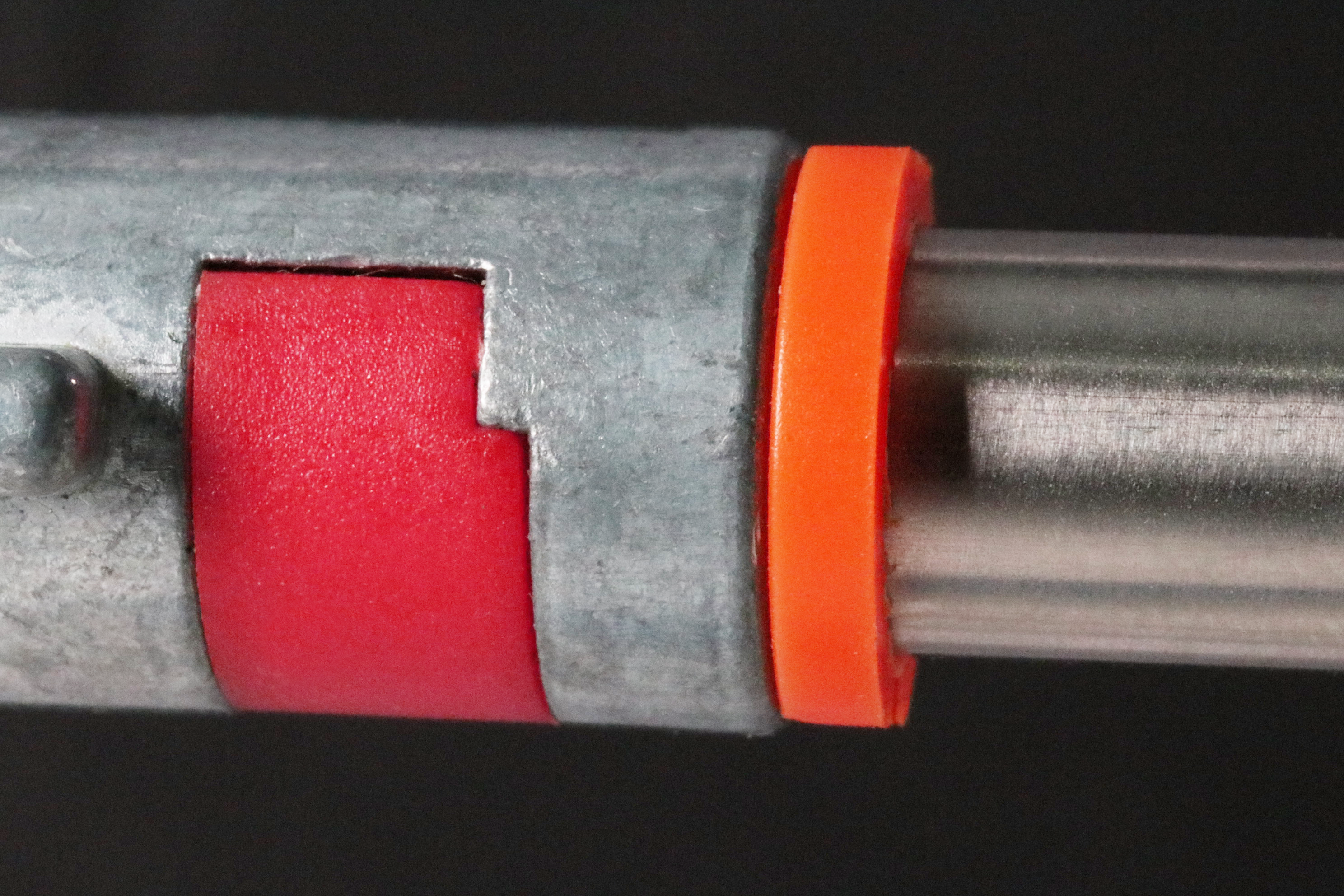

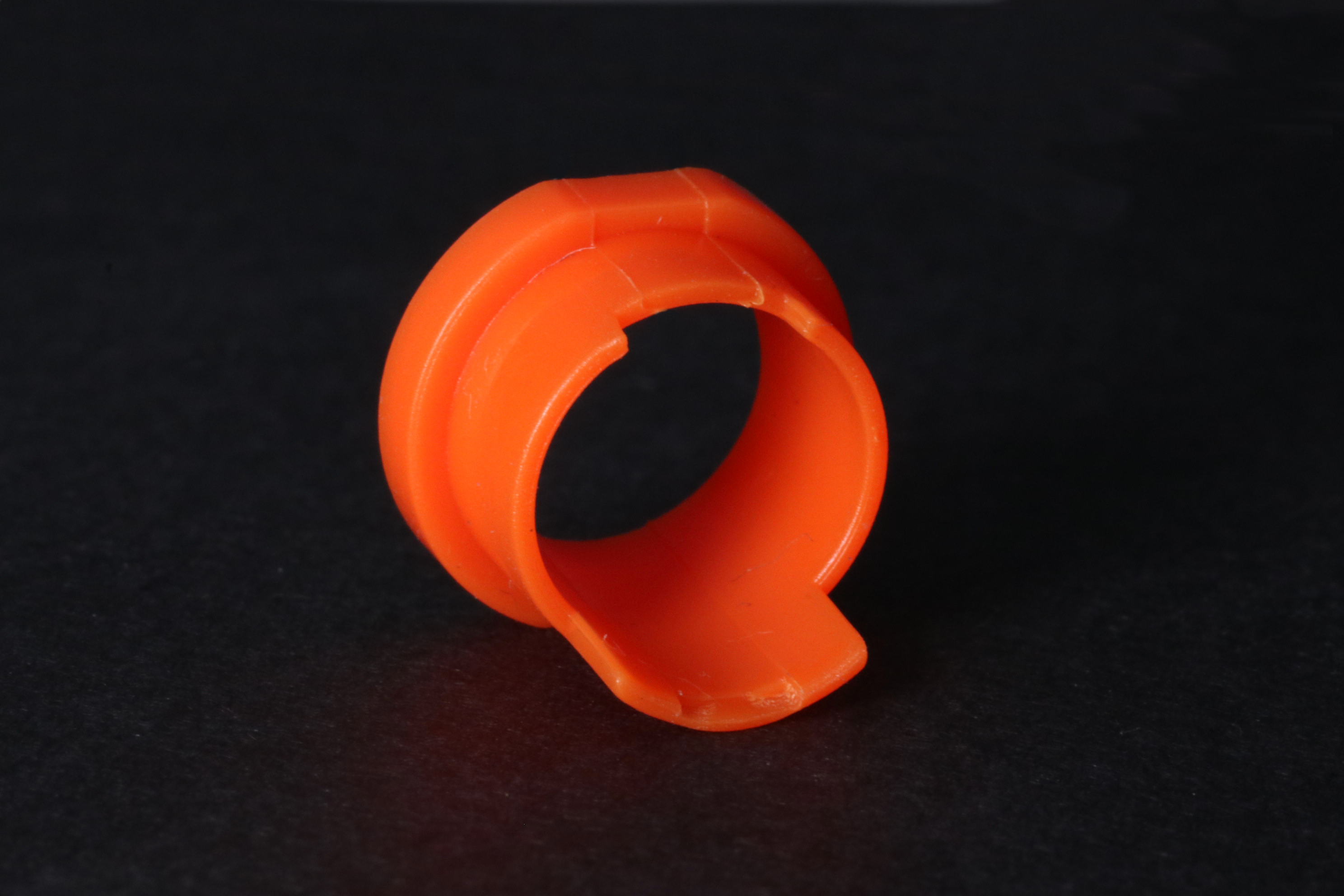

The Advanced locking ring is designed to replace the current Oring (Normally brass) ring at the end of setting up the hop unit, however, with the original, there is a tendency for a wobbly gap in between the components which would tilt the barrel at an angle.

Once the new Oring is installed, it will ensure a snug fit to restrict the motion of the barrel that is inside the hop-up chamber. It will secure the inner barrel and maintains itself steadily locked in the true horizontal position. Even when shots are fired, which is the moment where there is the most stress and vibration at the hop-up, the Oring will ensure the structure is intact.

This in turn will create a dependable system for the BB to travel down the barrel undisturbed for the most consistent and accurate shots.

The new Advanced Oring is also designed longer in size to lock more of the inner barrel and hop-ups surface area to further stabilize the sensitive system.

Features

- Fully lock on the inner barrel and hop-up chamber.

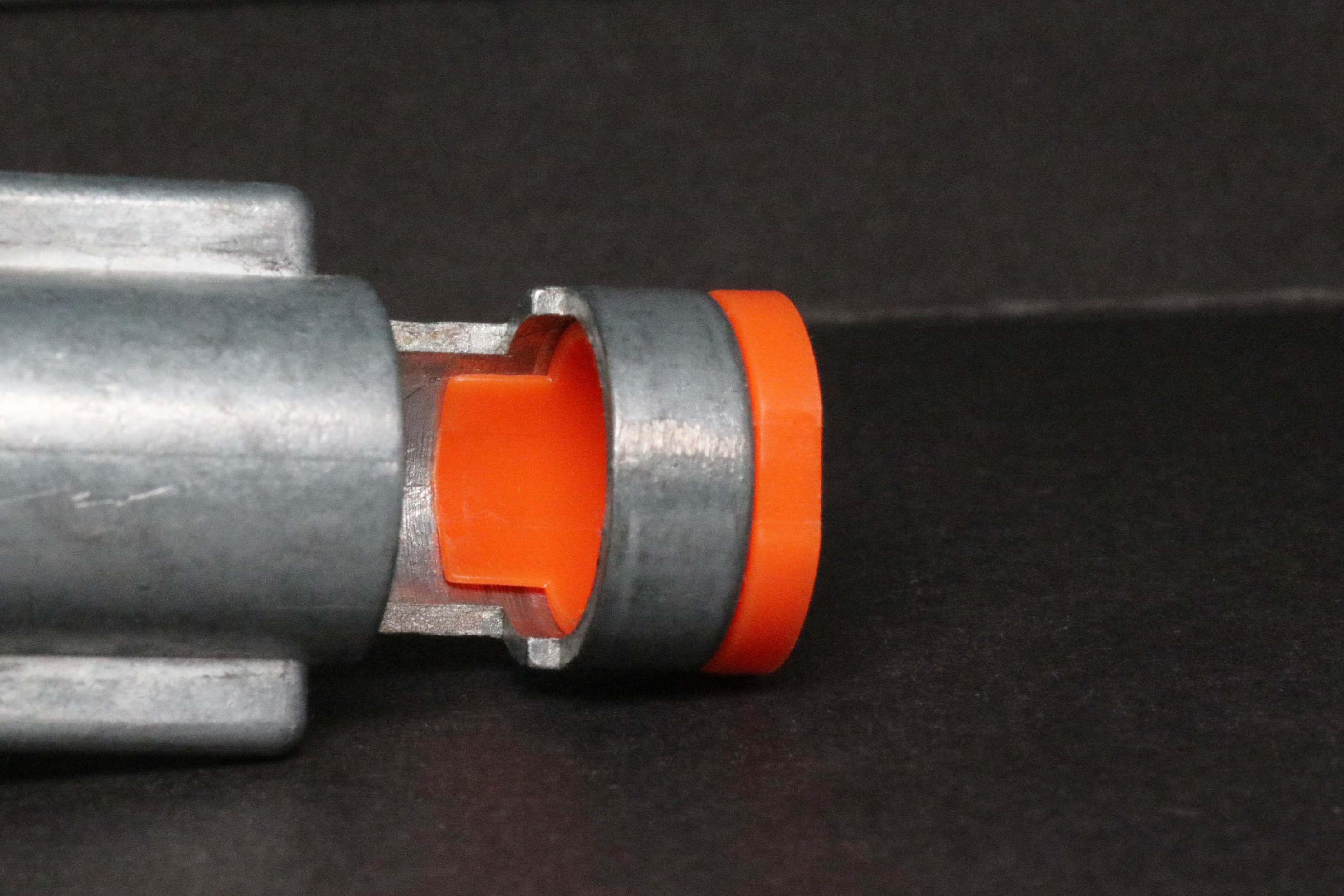

- Elongated O-ring to latch onto the inner barrel.

- Stabilized System Prevents any vibrational shift on the hop set-up.

- Improve shooting consistency.

- Tough Polycarbonate Construction. 6x silicone o-rings are also included with the package used to replace the spring that goes along the inner barrel. Tests incrementally you need for a perfect fit.

In general, anything that moves in the rifle especially in the hop-up/ inner barrel should be strictly locked down to eliminate the factors that could affect the consistencies of the shots fired.

This upgrade is for those who would strive for absolute perfection for their gun setup.

Compatibility

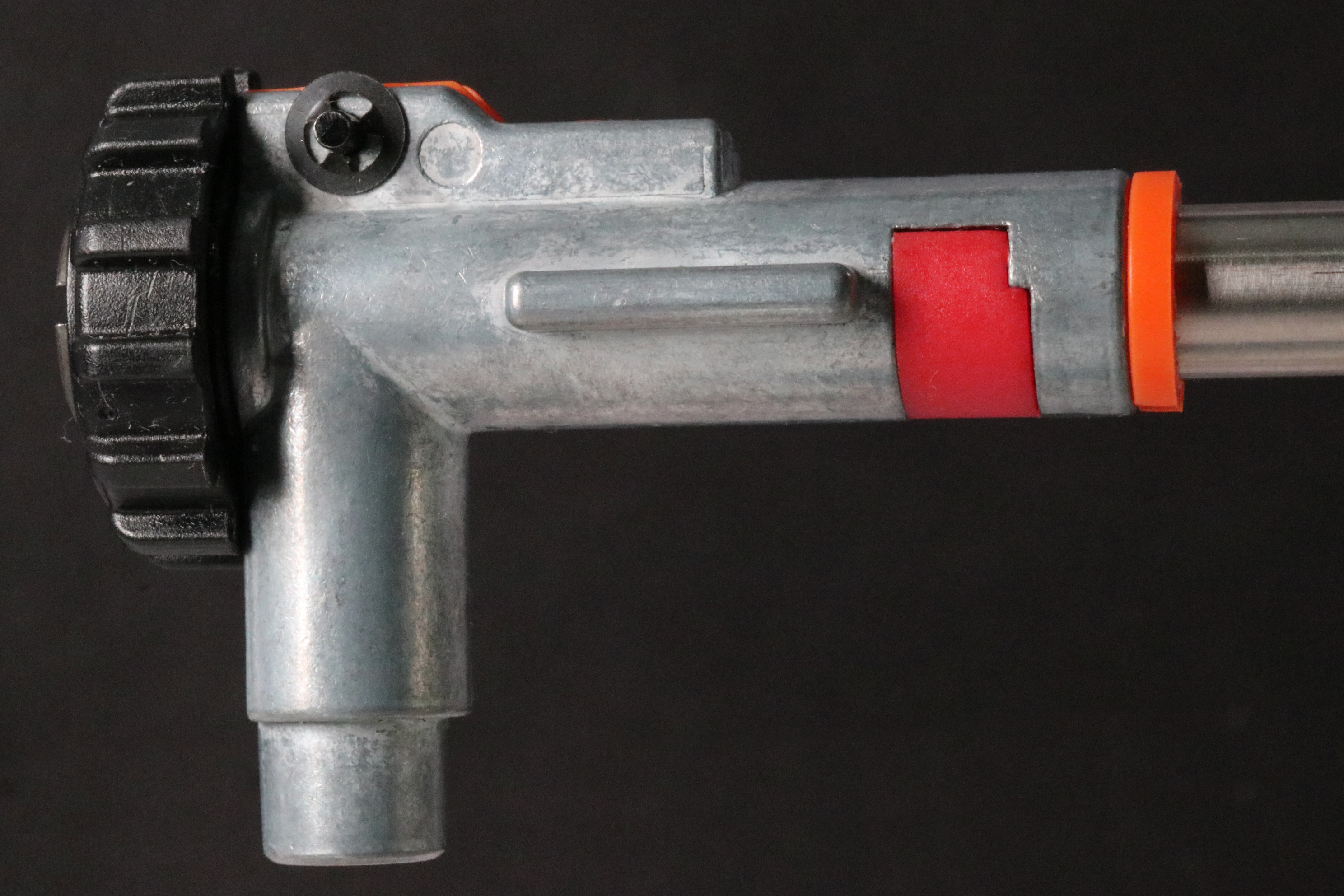

✔️ICS Metal Rotary

✔️KWA Rotary

* Please note the ICS or KWA hop-up chamber is not included specifically and are for demonstration purposes only - this is an upgrade item made FOR the hop-up unit itself*

Installation tips

Warning: Due to the manufacturing tolerances of your hop chamber and the Inner barrel you intend to use, light sanding may be required to ensure the perfect fit.

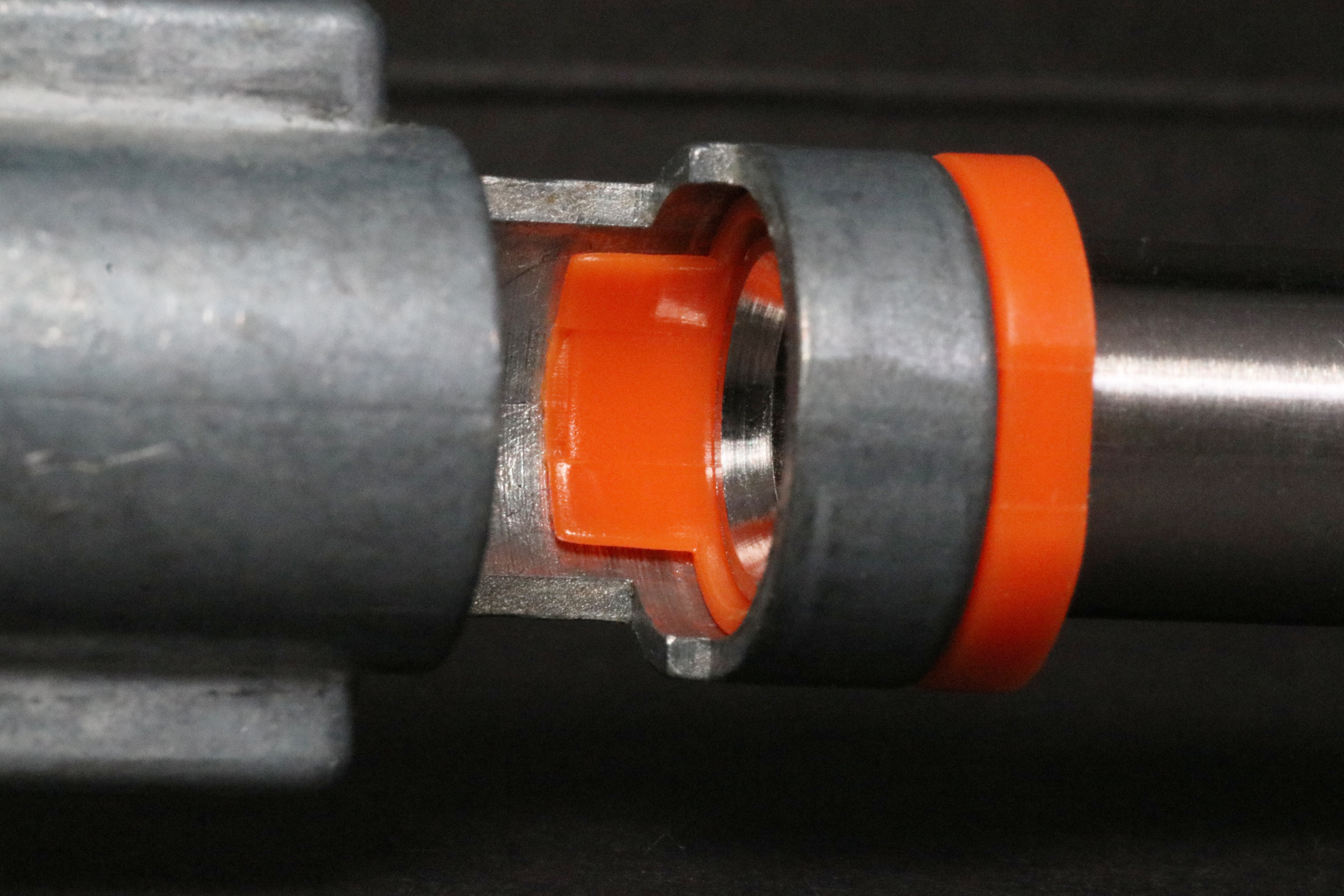

I. The Oring is designed to be a tight fit for the best performance. Try the O-ring onto the inner barrel first. If it's too tight, you can sand inside the ring until it's nice and snug.

II. Next try fitting just the O-ring into the Hop-up chamber. If too tight you can sand off the surface of the outer part of the ring until it's snug but not too tight.

III. Once you are happy, it may be difficult to slide the O-ring down towards the hop-up chamber. We tend to use an adjustable spanner to assist in sliding it down until it's locked. Add silicone oil inside would make it easier to slide also.

Special Note it is normal in many cases for the O-ring not to be fully inserted into the chamber, due to tolerances between the chamber and inner barrel brands. This will leave a slight gap of around 0.5mm. Do not try to force it any further as that could damage the Oring and/or hop-up chamber.

IV. To removes the O-ring for maintenance, ensure the hop-up is on the neutral 0 settings, and simply twist the inner barrel. The o-ring will twist off alongside the barrel.